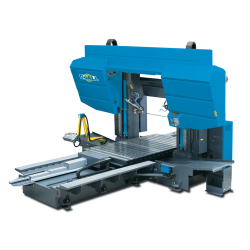

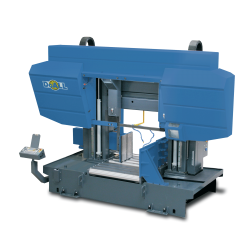

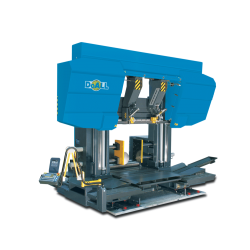

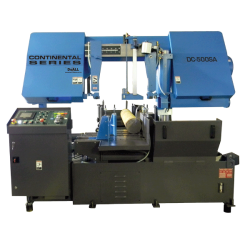

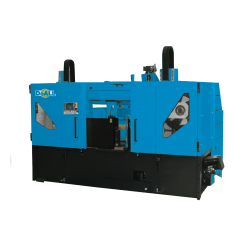

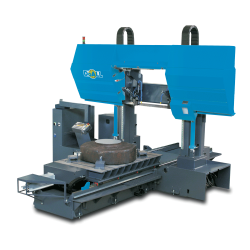

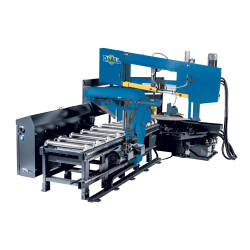

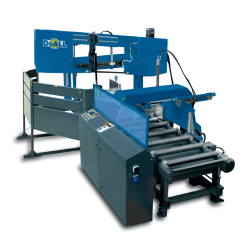

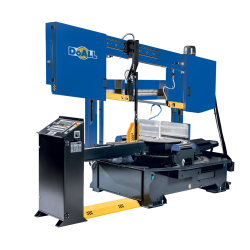

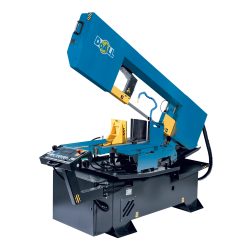

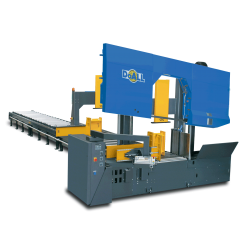

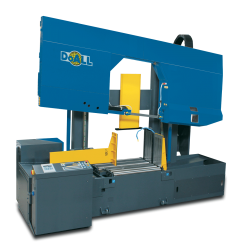

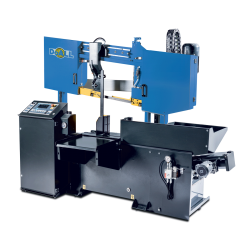

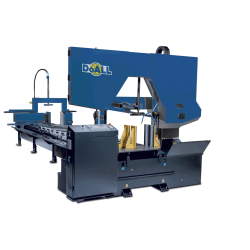

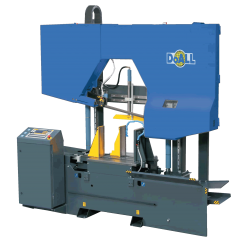

DOALL DC-280NC 11" X 11-3/4" CONTINENTAL SERIES AUTOMATIC HORIZONTAL PRODUCTION COLUMN BAND SAW

$38,900.00

- Stock: In Stock

- Model: DC-280NC

- Weight: 3,858.00lb

- Dimensions:

- 79.00in x 83.00in x 51.00in

- SKU: DC-280NC

|

|

|

|

-250x250.jpg)

-250x250w.png)

-250x250w.png)

-250x250.jpg)

-250x250.jpg)

.png)